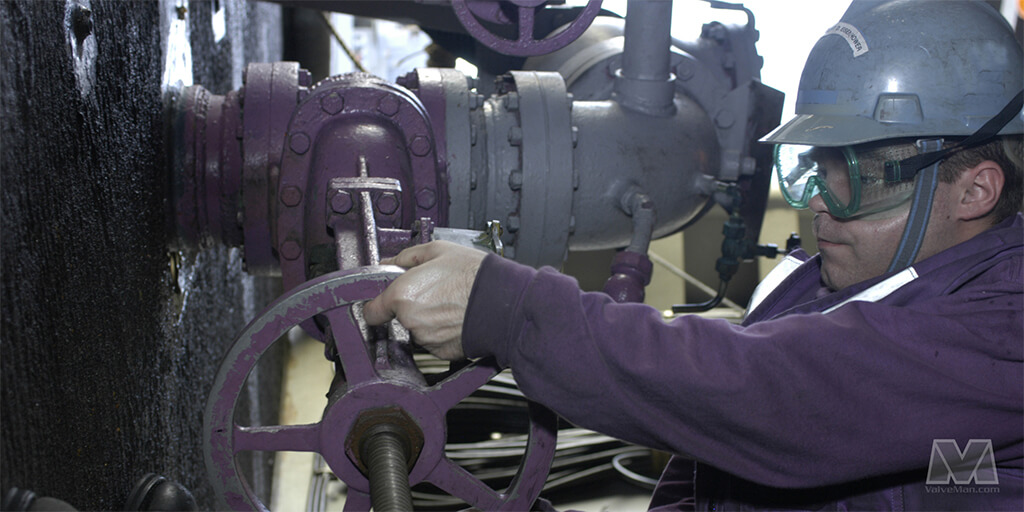

Mining operations demand powerful and reliable machinery that can perform under harsh conditions. Oil-cooled electric motors are ideal for mining equipment due to their ability to operate in extreme temperatures and handle heavy loads. This article explores the role of oil-cooled motors in mining operations and their connection to geomembranes for environmental safety.

How do oil-cooled motors support mining operations?

Oil-cooled motors are crucial in mining because they:

- Prevent Overheating: Mining equipment often runs for long hours in high-temperature environments. Oil cooling ensures that the motor stays at a stable temperature, preventing overheating and system failure.

- Improve Efficiency: Oil-cooled motors are more efficient than air-cooled motors in handling the high power requirements of mining machinery.

- Increase Durability: The oil provides both cooling and lubrication, reducing wear on components and extending the motor’s lifespan.

What are the benefits of oil-cooled motors for mining equipment?

In mining, oil-cooled motors provide:

- High Power Capacity: These motors can manage the high power demands of mining equipment such as excavators, drills, and conveyors.

- Reliability: The consistent cooling provided by oil ensures that mining machinery operates reliably in tough conditions.

- Long-Term Savings: The reduced need for repairs and longer motor lifespan offer significant cost savings over time.

How do oil-cooled motors and geomembranes work together in mining?

In mining, geomembranes are used alongside oil-cooled motors to provide environmental protection. Geomembranes are used to contain any hazardous spills, such as oil leaks from the motors, preventing contamination of the surrounding environment and water sources.

What maintenance is necessary for oil-cooled motors in mining equipment?

For mining equipment, proper maintenance of oil-cooled motors is crucial:

- Oil Replacement: Regularly replace the oil to maintain its cooling and lubricating properties.

- System Inspections: Periodically inspect the cooling system and motor components to ensure there are no blockages or leaks.

- Performance Monitoring: Use monitoring tools to track motor temperature and performance to identify any potential issues before they cause failure.

Oil-cooled motors are essential for ensuring the reliability and efficiency of mining equipment. They help handle the high power demands and extreme conditions of mining operations. Paired with geomembranes for environmental protection, oil-cooled motors contribute to both operational success and sustainability in the mining industry.