In industrial settings, particularly those involving flammable or explosive materials, safety is paramount. An explosion proof slide gate motor is a critical component designed to operate safely in these hazardous environments. These specialized motors provide reliable operation for sliding gates, ensuring controlled access while minimizing the risk of ignition from electrical sources. This article explores the features, benefits, and applications of explosion proof slide gate motors, as well as their relationship with safety measures like geogrid systems.

What is an explosion proof slide gate motor?

An explosion proof slide gate motor is an electric motor engineered to function safely in explosive atmospheres. It features robust construction and specific design elements that prevent sparks and overheating, reducing the risk of ignition in environments with flammable gases or dust.

Where are explosion proof slide gate motors commonly used?

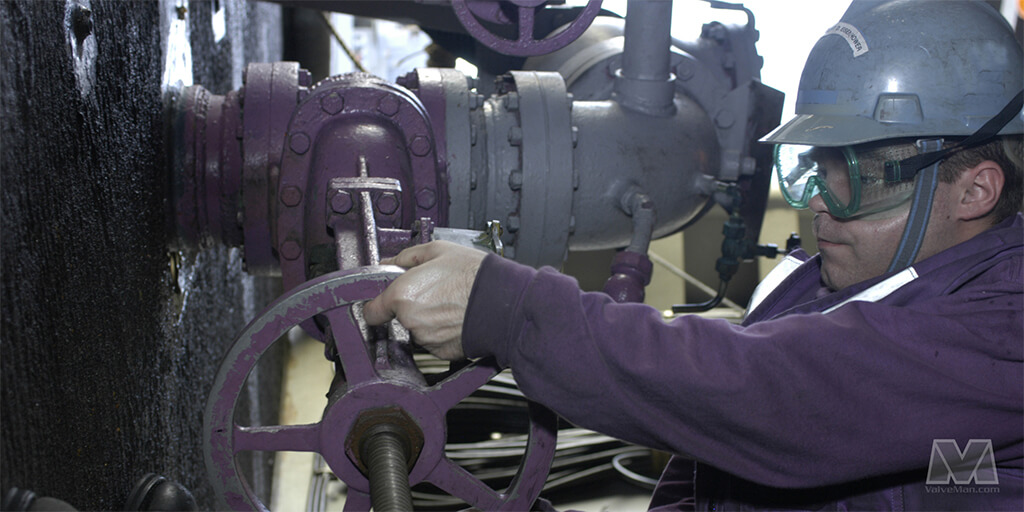

These motors are typically used in industries such as oil and gas, chemical manufacturing, and waste management. They are essential in locations where hazardous materials are present, providing safe and efficient operation of sliding gates for access control and material handling.

How does an explosion proof slide gate motor improve safety?

The design of explosion proof slide gate motors includes sealed enclosures, thermal protection, and other safety features that prevent ignition. By using these motors, industries can significantly reduce the risk of fires and explosions, thereby protecting personnel and equipment.

What is the relationship between explosion proof slide gate motors and geogrid systems?

Geogrid systems are often used in construction and civil engineering projects to enhance ground stability and support heavy loads. In environments where explosion proof slide gate motors are employed, geogrid can help ensure that the ground conditions are suitable for heavy machinery and traffic, contributing to overall safety and operational efficiency.

Explosion proof slide gate motors are essential for safe operations in hazardous industrial environments. Their robust design and safety features minimize the risk of ignition, making them invaluable in sectors like oil and gas and chemical manufacturing. Furthermore, the integration of geogrid systems can enhance ground stability, further promoting safety and efficiency in these critical applications. By choosing the right equipment, industries can ensure the protection of their workforce and assets while maintaining productivity.