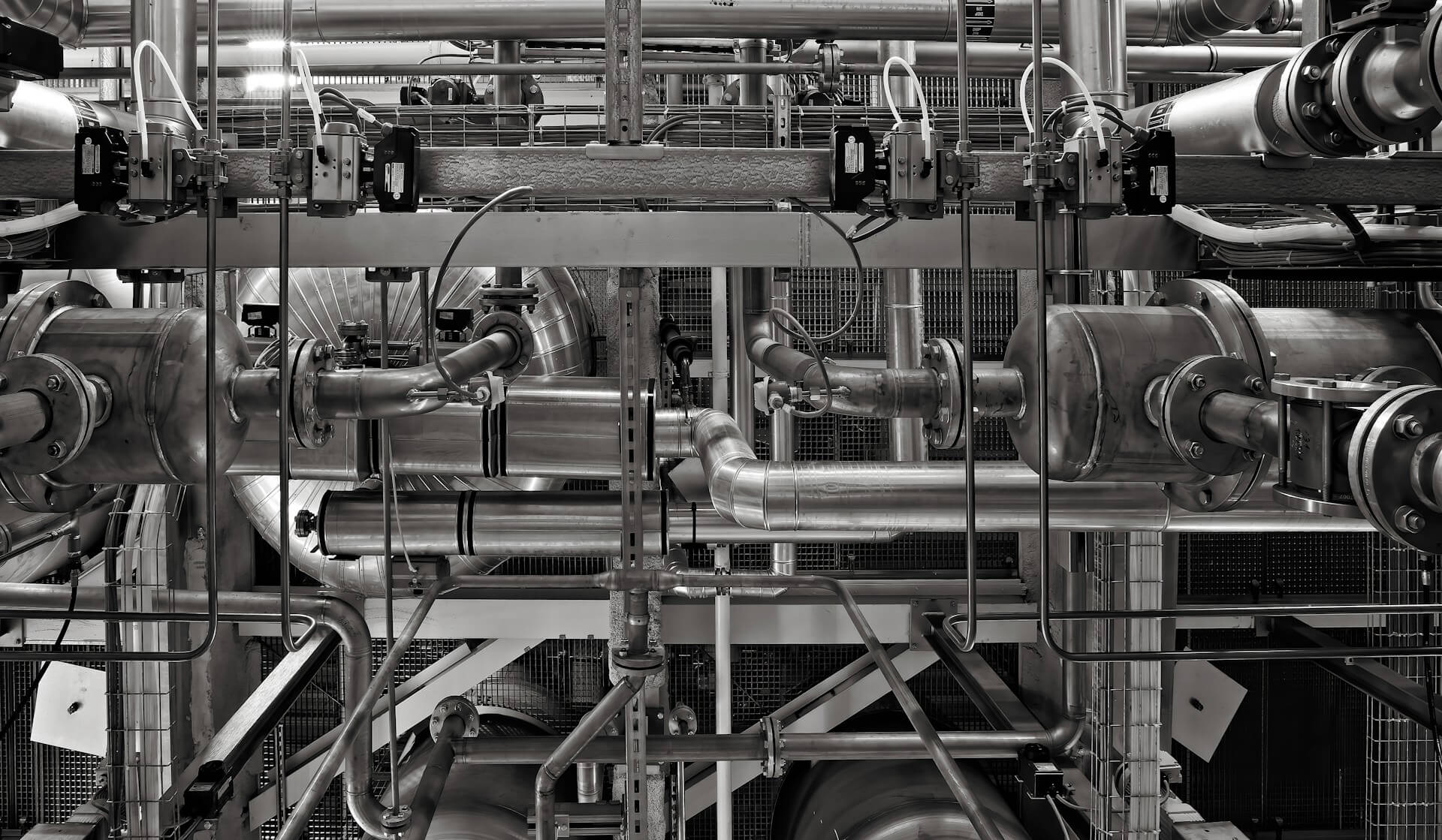

A Variable Frequency Drive (VFD) induction motor is a critical component in modern industrial applications. It provides precise control over motor speed and torque, making it a key element in energy efficiency and machinery performance. By adjusting the frequency and voltage supplied to the motor, VFDs allow for optimal operation across various applications, from HVAC systems to conveyor belts. This article explores how VFD induction motors work, their benefits, and their role in industries such as construction, where products like geosynthetics are commonly used.

What is a Variable Frequency Drive (VFD) induction motor?

A VFD induction motor is an electric motor that operates with a variable frequency drive to control the speed and torque of the motor. The VFD adjusts the power supplied to the motor, enabling fine-tuned performance for various industrial operations. The motor itself is typically an induction motor, which operates without permanent magnets and relies on electromagnetic induction.

How does a Variable Frequency Drive improve energy efficiency?

A VFD improves energy efficiency by adjusting the motor’s speed according to demand, preventing unnecessary energy waste. In traditional fixed-speed motors, the motor runs at full speed regardless of whether it’s needed, consuming more power. With a VFD, the motor runs at the precise speed required for the application, reducing energy consumption, especially in processes that involve fluctuating loads.

What industries benefit the most from using Variable Frequency Drive induction motors?

Industries such as manufacturing, HVAC, and mining benefit greatly from VFD induction motors. These motors are essential in applications that require adjustable speeds, such as conveyor systems, pumps, and ventilation systems. In the construction industry, VFD motors help control machinery that manufactures geosynthetics, optimizing processes like extrusion and weaving.

Can VFD induction motors be integrated with other systems?

Yes, VFD induction motors are highly adaptable and can be integrated with various control systems, including programmable logic controllers (PLCs) and building management systems (BMS). This integration allows for more precise automation and monitoring of industrial processes, increasing both productivity and safety.

Variable Frequency Drive induction motors offer significant advantages in terms of energy savings, control, and versatility across a wide range of industries. From manufacturing to construction, including processes related to geosynthetics, VFD motors help optimize operations and improve efficiency. As industries continue to seek more sustainable and cost-effective solutions, the role of VFD induction motors will only become more critical in driving innovation and performance.