Gear is an integral component in various mechanical systems, from everyday tools to complex machinery. It plays a crucial role in transferring motion and torque between different parts of a machine, thereby influencing its overall performance. This article delves into the different types of gears, their applications, maintenance tips, and their relevance to industries that use geomembranes for enhanced functionality.

What are the different types of gears?

Gears come in several types, each suited to specific applications. The most common types include:

- Spur Gears: These have straight teeth and are used for transmitting motion between parallel shafts. They are simple and cost-effective.

- Helical Gears: With teeth that are cut at an angle, helical gears operate more smoothly and quietly than spur gears. They are used for applications requiring high-speed and high-load performance.

- Bevel Gears: These gears are designed to change the direction of the shaft’s rotation. They are commonly used in applications where shafts intersect at an angle.

- Worm Gears: These consist of a worm and a worm wheel, providing a high reduction ratio and are used in applications where space is limited.

How do gears impact mechanical efficiency?

Gears significantly affect mechanical efficiency by influencing the speed, torque, and direction of movement in a machine. Proper gear selection and alignment ensure smooth operation, reduce energy loss, and minimize wear and tear on other components. For instance, using the right gear ratio can enhance the performance of machinery and reduce the overall energy consumption.

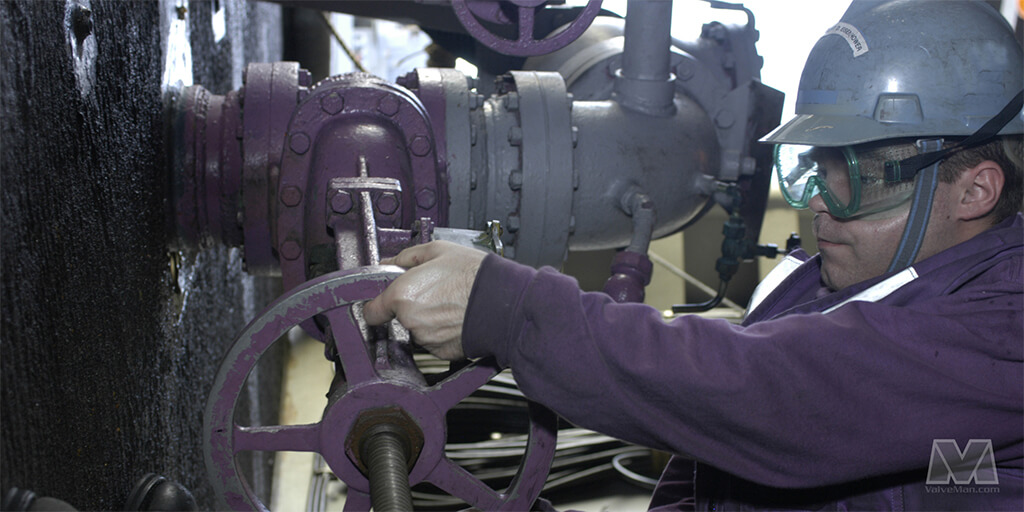

What maintenance practices are essential for gears?

To maintain gears in optimal condition, consider the following practices:

- Regular Lubrication: Gears require proper lubrication to reduce friction and prevent overheating. Use the recommended lubricant and follow the manufacturer’s guidelines.

- Inspection and Cleaning: Periodically inspect gears for signs of wear or damage. Clean them to remove debris and ensure smooth operation.

- Proper Alignment: Ensure gears are correctly aligned to avoid misalignment issues that can lead to premature wear or failure.

- Replace Worn Parts: Address any signs of wear or damage promptly by replacing worn gear components to avoid further damage and maintain efficiency.

How does gear technology relate to geomembranes?

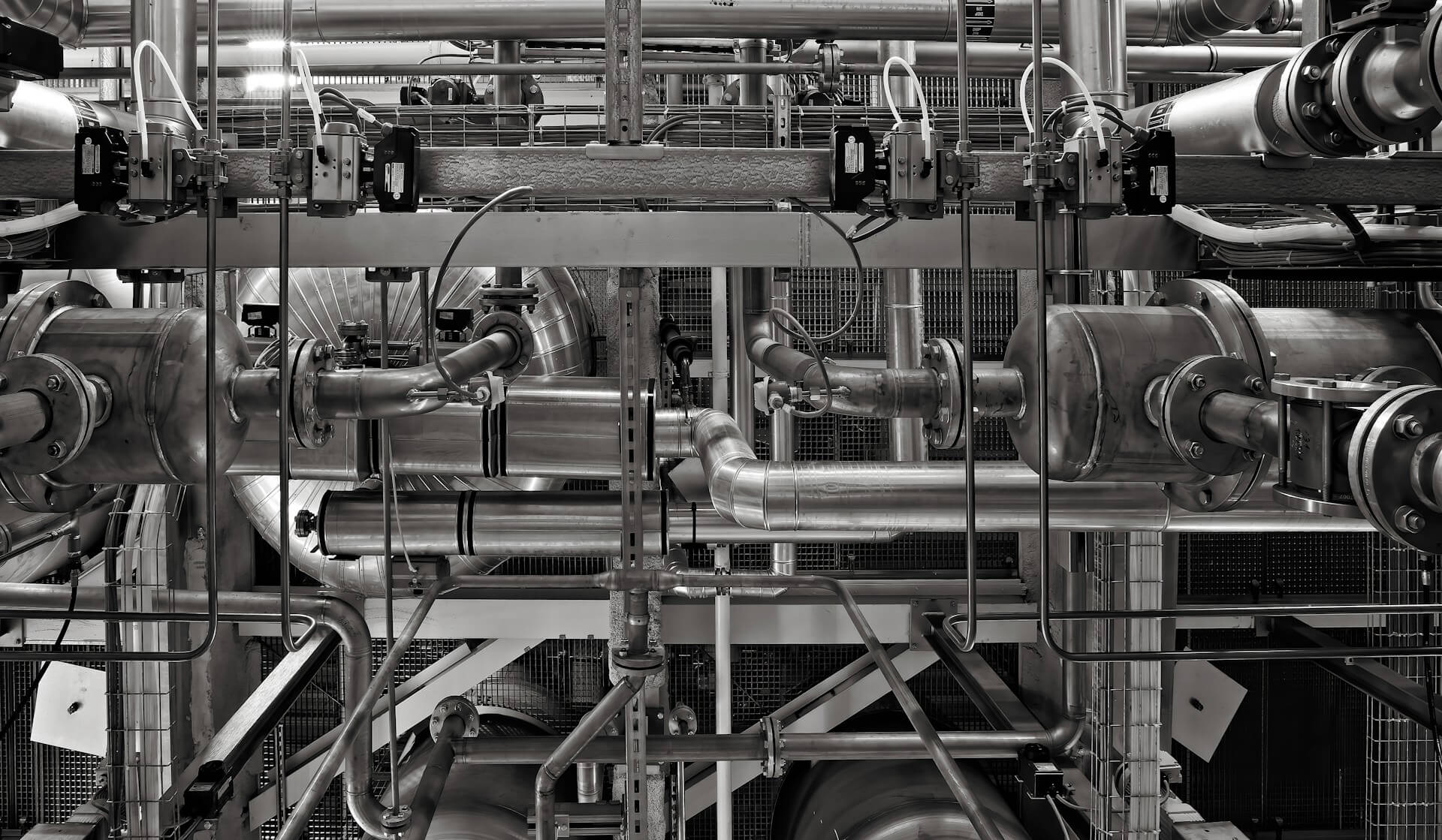

In industries where geomembranes are used for applications like environmental protection or construction, gears play a vital role in the machinery that processes or installs these materials. For example, gear systems are often employed in equipment like welding machines or rollers that handle geomembranes. Proper gear maintenance ensures the reliable operation of such equipment, contributing to the effective installation and longevity of geomembranes in various applications.

Gears are fundamental elements in mechanical systems, essential for transferring motion and torque efficiently. Understanding the types of gears, their impact on mechanical efficiency, and proper maintenance practices can greatly enhance machinery performance. Additionally, in industries utilizing geomembranes, gears are crucial for the reliable operation of equipment that processes these materials. By focusing on gear maintenance and technology, you can ensure smooth operations and extend the lifespan of both machinery and geomembranes.