Valves are essential components used in various industries to control the flow of liquids, gases, and other substances. They are crucial for regulating pressure, controlling flow rates, and ensuring system safety. In this article, we will explore the different types of valves, their applications, and how they interact with other materials, such as geomembranes, in industrial settings.

What are the different types of valves and their functions?

Valves come in numerous types, each serving specific functions. Common types include:

- Gate Valves: Primarily used to start or stop flow. They are ideal for applications requiring minimal pressure drop.

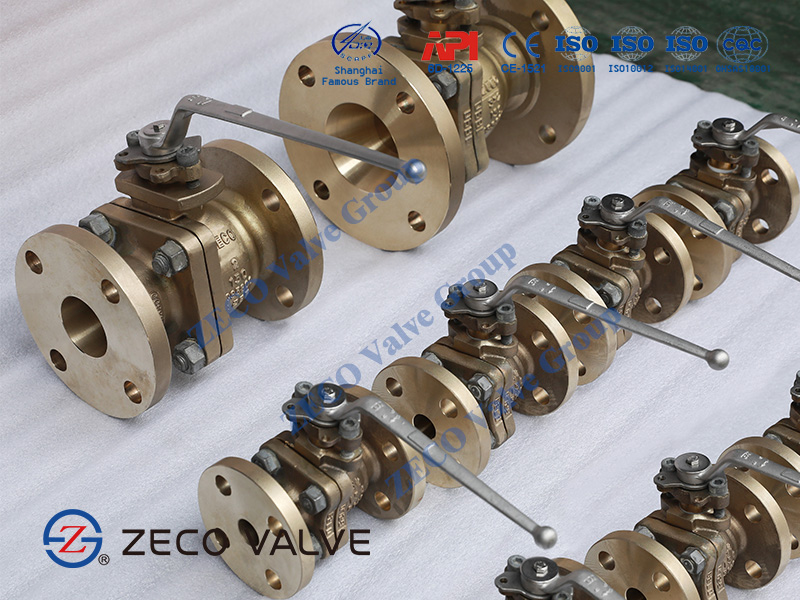

- Ball Valves: Feature a spherical ball with a hole through the middle that controls flow. They are known for their durability and reliability.

- Butterfly Valves: Utilize a rotating disc to regulate flow. They are compact and used in large-volume applications.

- Check Valves: Prevent backflow in a system, ensuring that fluid flows in only one direction.

Each type of valve is designed to handle particular pressures, temperatures, and types of fluids.

How do valves contribute to system safety and efficiency?

Valves enhance system safety and efficiency by:

- Regulating Flow: They control the amount of fluid passing through the system, preventing overflows and system damage.

- Pressure Management: Valves help maintain and manage pressure levels within a system, reducing the risk of burst pipes or leaks.

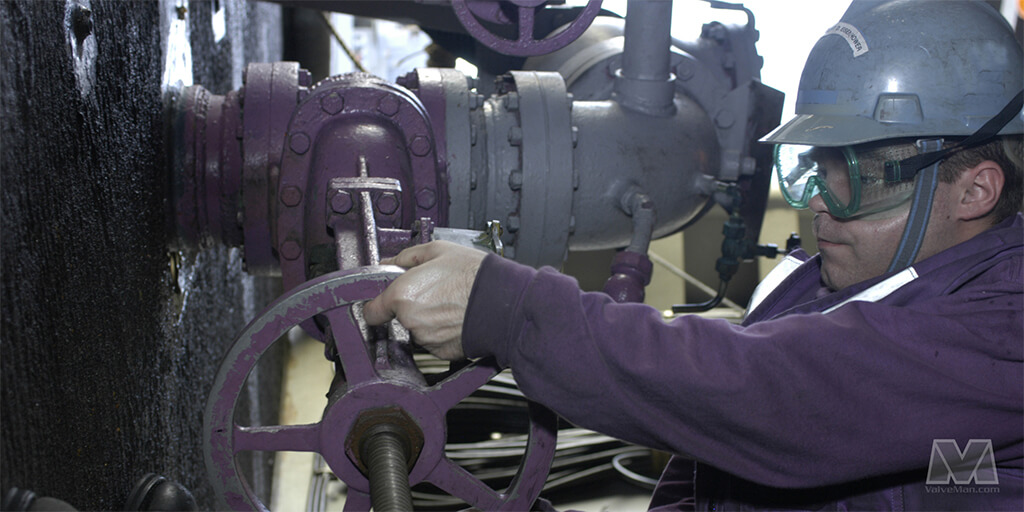

- Isolation: In case of maintenance or emergencies, valves can isolate sections of a system, minimizing downtime and damage.

- Controlling Temperature: Some valves, like thermostatic valves, manage the temperature of the fluid, protecting sensitive equipment.

What role do valves play in applications involving geomembranes?

Geomembranes are synthetic liners used in various applications such as landfills, mining, and water reservoirs to prevent leakage and contamination. Valves interact with geomembranes in the following ways:

- Leak Detection: Valves are used in systems with geomembranes to control and monitor the flow of fluids, helping detect any leaks in the geomembrane liner.

- Pressure Control: In systems where geomembranes are employed, valves regulate the pressure of the contained fluids, ensuring that the geomembrane remains intact and functions effectively.

- Maintenance Access: Valves allow for access to the fluids in systems lined with geomembranes, facilitating easier maintenance and repair without disturbing the geomembrane itself.

How should one choose the right valve for a specific application?

Selecting the right valve involves considering several factors:

- Fluid Type: Choose a valve material compatible with the fluid’s chemical properties.

- Pressure and Temperature: Ensure the valve can handle the pressure and temperature of the system.

- Flow Requirements: Match the valve type to the flow rate and control needs.

- Maintenance Needs: Consider how often the valve will require maintenance and choose one that is easy to service.

Consulting with experts and reviewing system specifications can help in selecting the most suitable valve for your application.

Valves are indispensable in managing the flow and pressure of fluids across various industries. Understanding the different types of valves and their functions is essential for maintaining system safety and efficiency. When working with geomembranes, valves play a critical role in leak detection, pressure control, and maintenance access. By carefully selecting the appropriate valve for each application, you ensure optimal performance and longevity of your systems.